Banana yarn is actually a thing and a truly fascinating one! If you love all things yarn and sustainable, you’ll definitely want to find all about this 100% biodegradable, vegan yarn.

In this article, we’ll first see where banana yarn comes from. Then, we’ll cover its production process, and see how banana yarn can make the fiber world a better place.

A little Banana background

Bananas are one of the cheapest and most consumed fruits worldwide, and banana plantation is one of the largest and ever-growing in the world.

The Food and Agricultural Organization of the UN (FAO) estimated that in 2017, the global production of bananas reached a record of 114 million tonnes, up from around 67 million tonnes in 2000.

The biggest producers of bananas are India and China, which both produce bananas mostly for their domestic market. So, when it comes to banana exporters, we have to look at countries like Ecuador, the Philippines, Costa Rica, Colombia, and Guatemala.

If you live in the US or Europe, you’ll probably be familiar with at least two kinds of bananas, the Cavendish type, and the plantains. However, these are not the only bananas out there. In nature, there are actually more than a thousand varieties of banana!

Interesting fact

Cavendish-type bananas account for about 47% of all global banana production. The main reason is that these are the easiest bananas to grow, and they are better for export because they are more resilient to the effects of global travel.

At this point, it might also be nice to learn something about the biology of bananas. For those of you who have no clue where bananas come from…

Shocking news, bananas come from a plant and not a tree, and technically, they are berries, not fruits.

One banana plant will only fruit once in its lifetime. This means that the plant grows, flowers and fruits, usually in the summer. Then, after harvesting, it is cut down to the ground to make room for the next plant, which will grow from the creeping underground stem.

Now, imagine the huge areas dedicated to banana cultivation and the huge number of plants that are cut down around 2-4 times per year! Those are a lot of plants that are just waste material.

As we just said, banana plantation results in a high number of cut-down plants, which are destined to the landfill.

However, the production of banana fibers can give a new life to all those wasted plants. How? Easy… The precious banana fibers are all nested in the banana barks!

Note: this post contains affiliate links. This means that if you purchase something through the links on my blog, I might earn a commission. This will not have any effect on the price you pay. For more info, please, see my Privacy Policy.

What is Banana Yarn?

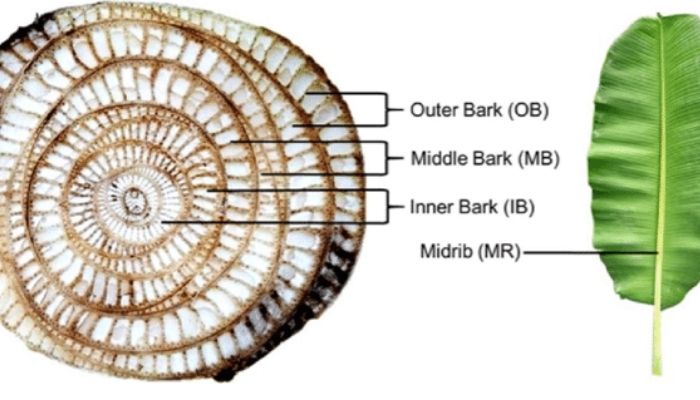

Banana fiber yarn is a natural bast fiber derived from the inner bark (or phloem) of banana plants.

It is a very eco-friendly material, which also has the advantage of being completely biodegradable.

This yarn is also known as banana silk, due to the shiny and silky aspect of the most precious fibers, or Musa yarn, from the Musa genre to which the banana plant belongs.

Properties of Banana Fibers

Banana yarn can have varying properties depending on the part of the plant that was used for its production.

In general, we can say that:

- Banana fibers are among the strongest and most durable natural fibers.

- They have great breathability and moisture-wicking properties.

- Banana fibers are finer than other bast members, including bamboo.

- On the downside, they do not stretch much.

What to make with banana fiber?

The thick and sturdy yarn that comes from the outer part of the phloem is often used for rugs, maritime ropes, paper, and packaging material for agricultural products. This yarn is also called Manila hemp because it is similar to hemp, and in the past, it was mainly produced in the Philippines.

The softer and finer yarn produced from the inner part of the phloem mostly finds applications in the weaving of lightweight fabrics. These fabrics are very popular in Japan for summer wear and for the manufacturing of traditional kimono and kamishimo garments.

The Production Process of Banana Yarn

The production of banana yarn is not new. On the contrary, banana yarn has been around for a very long time in several Asiatic countries, including the Philippines, Japan, and India. However, this product never became hugely popular, especially in the Western world.

However, in recent years, the fashion industry has started to seek more sustainable alternatives to massively produced fibers, natural or synthetic. And this is where banana yarn comes into play.

So, let’s take a look at how we can go from banana plants to beautiful yarn!

Peeling

The first step in the production of banana fibers is the peeling of the outer part (the green peel) of the pseudostem of the plant. At this stage, we are basically left with the inner bark.

Keep in mind that the “inner” you go in the bark, the softer and higher in quality the fibers are!

Retting

In the phloem, banana fibers are found as bundles of cellulose, hemicellulose, lignin, and up to 2% of pectin and waxes (see this paper).

Thus, the first step in the production of banana fibers consists of the extraction and separation of the cellulosic fibers from all the other substances. This process is known as retting.

The key point here is really to get rid of lignin, pectin, waxes, and all the non-cellulosic constituents present in the phloem and unfortunately for us, the sole mechanical separation is not able to separate the lignin.

Thus, other methods would be preferable.

Currently, retting often involves soaking the banana barks in water and/or sodium hydroxide (and occasionally other chemicals like KMnO4, benzoyl chloride, stearic acid, etc). Obviously, this is not ideal because there are resulting chemical baths to handle, purify, and dispose of into the environment.

A more environmentally friendly option is the use of biological processes, such as immersed or solid-state fermentations. These methods also have the advantage of not breaking the fibers.

Drying

The extracted fibers are usually bunched together and dried in the sun. At this stage, all fibers are together, there is no separation between high-quality fibers and low-quality ones.

Grouping…

Once the fibers are dry, it is much easier to physically separate them, and they can be grouped based on their thickness and quality. Fibers of the same group are knotted together to form a long strand.

…Or Opening and Carding

Banana fibers can be blended with any other kind of yarn, natural or synthetic, on an industrial scale. To obtain these blended yarns, banana fibers are first opened with a short fiber opener and then carded together with the new yarn to provide some support to the fibers.

Banana fibers can blend nicely with cotton, wool, or polyester.

Spinning

The final step is spinning. Here, fibers are spun into yarn and made ready to use!

What is banana silk yarn?

Now that you know more about how to make banana yarn, you also know that the quality of the yarn can vary quite a bit depending on which part of the inner bark they come from.

Banana fibers derived from the outer peel are rough and coarse fabrics, a bit like jute.

On the other hand, banana fibers derived from the inner peel are softer, are more silk-like, hence the name banana silk. This yarn is more difficult to produce and get, so it usually costs more.

Where to Buy Banana Yarn

- Darn Good Yarn is a US-based, online ethical yarn store. Their offer of banana yarn is Banana Fiber Yarn, which is handspun and hand-dyed by women in Nepal. The yarn is very silky and sturdy, which makes it ideal. There are occasional breaks in the yarn which you will have to unknot before using.

- The Woolery is a US-based online store that looks like a heaven of fibers! In the huge selection of beautiful yarns, they also offer this natural and dyed banana yarn.

- Yarn Yarn is a UK-based yarn seller who mostly offers ethical yarns. You can find her banana yarns both on her website and on Etsy.

- Fiber2Fashion offers the opportunity to connect with several banana yarn producers from China and India.

- Several other options are also available on Etsy.

Is Yarn the Only Sustainable Thing About Bananas?

While the production of banana fibers has the advantage of being very environmentally friendly, the same cannot be said about banana cultivation.

So, all in all, can we consider banana yarn really sustainable?

If we take into account the deforestation that banana cultivation causes and monoculture with all its devastating impacts on ecosystems, well, I am not sure banana yarn can still hold its eco-friendly title.

Moreover, the banana plantation is one of the most impactful plantations on the environment, as it requires a high amount of pesticides, damaging for both the environment and the workers.

It is true though that cotton plantation is possibly even more devastating on the environment, so this should be kept into account…

In my opinion, banana yarn is a great way to upcycle agricultural waste resulting from the current massive production of bananas.

However, in the long future, we will probably have to rethink the way we manage natural resources on the planet, and maybe stop the huge monocultures like banana plantations.

One final thought about the future of the bananas we know, i.e. the Cavendish-type bananas, there is a threatening pathogen that is attacking most banana cultivations around the world. To read more about this topic, you can check here and here!

I hope that you enjoyed reading this article and I would love to know your thoughts about this fascinating fiber! Feel free to leave a comment or share your thoughts and ideas on Facebook or Instagram using the hashtag #raffamusadesigns

Find out more yarn fibers here on the blog…

Can you provide references for the article? Where I can read more about this fibre from reputable sources? Thank you.

Hi, the most reliable resources are scientific publications. You can find many by searching for “banana fiber” on Google Scholar. These are the links to a few articles that you can access for free:

https://www.researchgate.net/profile/K-Vadivel-3/publication/331732899_A_Review_Paper_on_Design_and_Fabrication_of_Banana_Fiber_Extraction_Machine_and_Evaluation_of_Banana_Fiber_Properties/links/5c8b647a45851564fade62eb/A-Review-Paper-on-Design-and-Fabrication-of-Banana-Fiber-Extraction-Machine-and-Evaluation-of-Banana-Fiber-Properties.pdf

https://www.mdpi.com/1996-1944/9/5/370/htm

https://journals.sagepub.com/doi/abs/10.1177/155892500800300207

https://pubs.acs.org/doi/full/10.1021/jf8003674

Happy reading 🙂